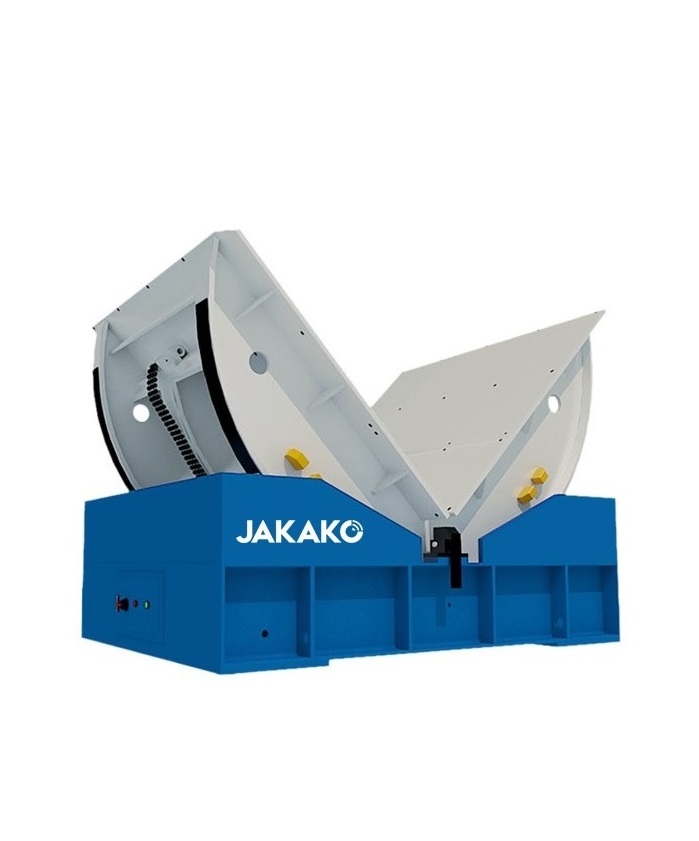

Handling and Lifting

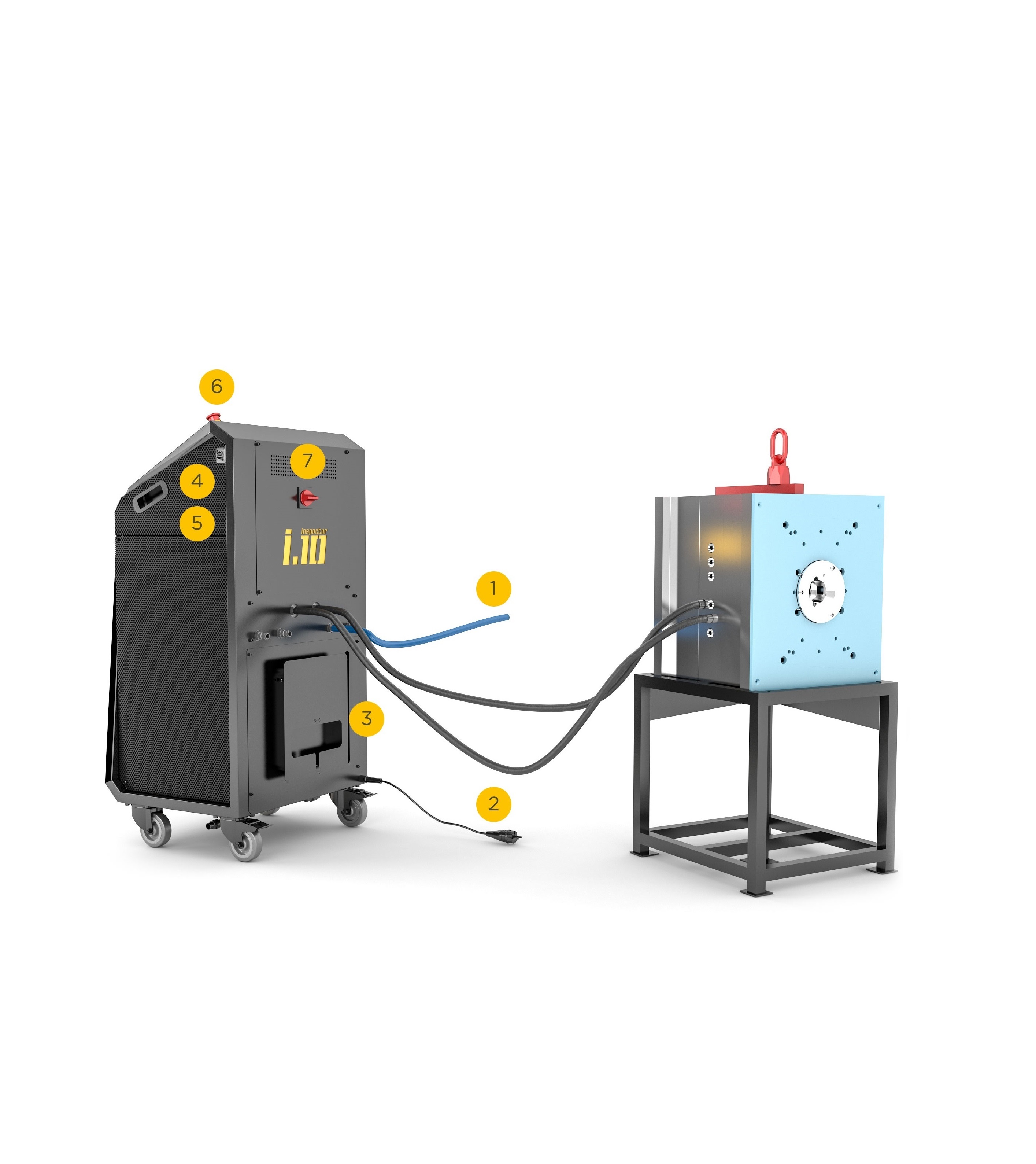

Various solutions for easier and safer handling of heavy moulds such as Meusburger air-cushioned assembly table for moulds up to 5 tons, RUD separators for moulds up to 10 tons, and JAKAKO turnover machines for moulds up to 50 tons. RUD high-quality lifting solutions such as lifting points, chains, hooks, master links, and tensioners offer a safe and efficient lifting of your heavy moulds.